Discover why understanding vibration is crucial for industrial lighting applications.

The Significance of Vibration in Industrial Lighting

Understanding the impact of vibration is crucial when it comes to selecting equipment, particularly light fixtures, for industrial sites. Vibrations, often caused by heavy machinery and industrial processes, are a common occurrence in these environments and can have a significant effect on the reliability and performance of electronic equipment, including lighting fixtures. It is imperative for lighting manufacturers to test their fixtures for vibration in order to assess the potential effects on the integrity of the fixtures.

In the most demanding industrial environments, vibration not only affects the performance and longevity of lighting fixtures, but prolonged exposure to constant vibration can gradually lead to increased movement of rigidly installed industrial equipment.

Impact of Vibration on Legacy Lighting Technologies

Vibration can pose serious risks and challenges, especially for legacy lighting technologies. Fragile filaments and bulbs can break, leaving workers exposed to shattered glass, falling debris, sudden drops in visibility, and even harmful exposure to toxic chemicals like mercury.

However, modern LED lighting technology provides inherent protection against vibration due to its solid-state nature, absence of fragile bulbs or filaments, and lack of any harmful chemicals. It is important to note though, that not all LED lighting is suitable for the demanding conditions of industrial settings. Manufacturers must consider how their products are designed and tested to withstand such harsh conditions.

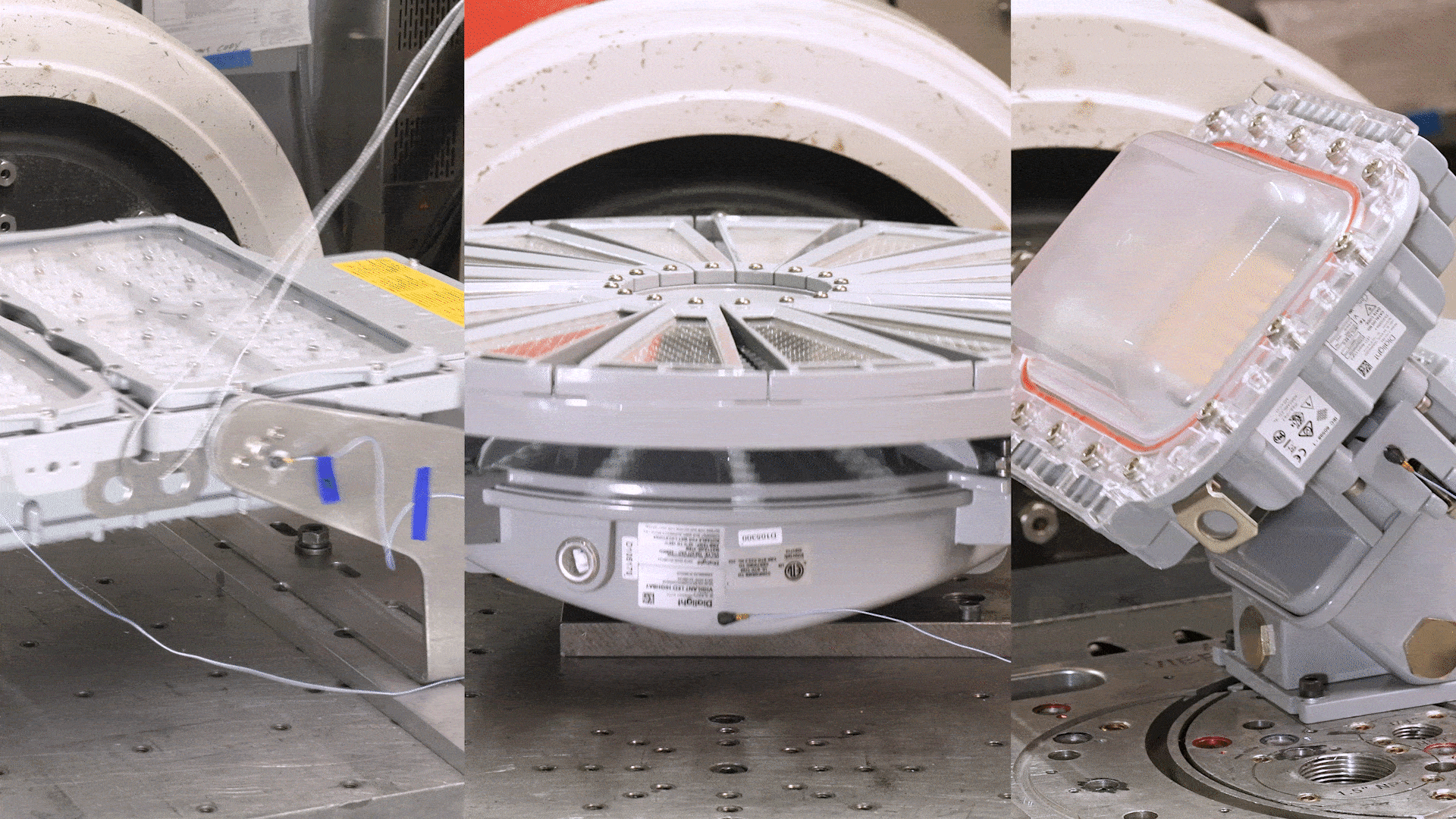

Dialight's Vibration Testing Methods

Dialight has established specifications for vibration testing that include testing on three perpendicular axes, a frequency range of 10-100 Hz, and a minimum of 1,000,000 cycles. Additionally, power supplies are potted to protect components from excessive movement and shock. It is crucial for lighting manufacturers to have a deep understanding of how their fixtures will perform and withstand vibration under different conditions over extended periods of time, as well as during short periods of large impulse input.

Vibration testing helps identify any areas of improper support in the fixture's design. Dialight's testing procedures proudly exceed the specifications of both Lloyds Register and IEC, ensuring that the test methodology accurately simulates permanently fixed installations in a range of applications.

Dialight subjects its industrial grade LED lighting fixtures to multiple vibration tests with different methods of imparting energy into fixtures, including; shock tests, endurance sweeps, and resonance dwell tests. Dialight’s unique approach to vibration testing has proven extremely effective in revealing failures that could otherwise have caused premature breakdowns in the field.

Explanation of Vibration Testing Procedures

Shock testing consists of applying a moderately high level force impulse into a fixture over a comparatively short time duration. Classical shock testing has the potential for producing adverse effects on the physical and functional integrity of all material. Shock testing is performed to determine the upper bound upper level of acceleration loads applied to resonant dwell tests and to test packaging that protects the material's physical and functional integrity.

Endurance sweeps are a vibration test where force impulse is applied to a fixture causing vibration over a given frequency range, from slow to fast, for a fixed duration. In this method, acceleration is applied slowly enough and held steady for a period long enough such that material has sufficient time to fully distribute the resulting internal loads. In vibration testing, endurance testing by sweeping minimizes the difficulties with asking the end user to apply the resonant dwell results to real world applications. In addition, this methodology gives confidence to end users over the greatest variety of use cases.

Resonant dwell testing consists of vibrating the fixture at its unique resonant frequencies where the energy input to the test unit is the greatest. The basic intention of the resonance dwell is not necessarily to reproduce the real environment, but to understand and uncover the failure modes at extreme physical energy input levels so that design robustness can be improved.

Safety and Longevity Assurance in Dialight's Products

Understanding how vibration affects lighting fixtures and identifying any failure points during the design phase helps Dialight to make products that are longer lasting and increase safety for customers.

Every detail from LEDs to power supplies to mechanical housings and mounting hardware is carefully considered and tested to perform optimally in harsh industrial conditions. Dialight also stands behind the performance and longevity of products with an industry-leading 10 year warranty.

Click here to watch Dialight's full vibration video and learn how Dialight can help protect your industrial lighting from vibration.